CHARGEPOINT EXPRESS 250

CLIENT

ChargePoint

YEAR

2018

CREDITS

ID by ChargePoint Image credit: ChargePoin

SERVICES INCLUDED

Project Management, Mechanical Concept Development, Detailed Design for Manufacturing, Industrial Design Integration, Analysis, Prototyping, Testing, Vendor Liaison

PHASES

Define

Validate

Integrate

Refine

Ramp

Case Study Details

Design for Extreme

Environments

Drivers and commercial fleets rely on ChargePoint charging stations throughout the world in climates ranging from searing heat and sun exposure to driving rain and icy cold. Alloy was tasked with ensuring that the external enclosure strategy and detailed part design met the specifications required for extreme conditions. One of the most challenging aspects of this requirement was managing water ingress from driving rain or hosing off, especially considering the extensive venting, large fans, and resulting air flow needed for the cooling systems. Alloy created concepts and prototypes for interlocking joints, seals, drainage, and baffles. We developed detailed test plans, conducted extensive environmental testing onsite, and worked with vendors to select qualified part materials. After our team incorporated test results and vendor feedback into the final design, the charging station ultimately met internal product specifications and passed testing requirements set by external regulatory organizations.

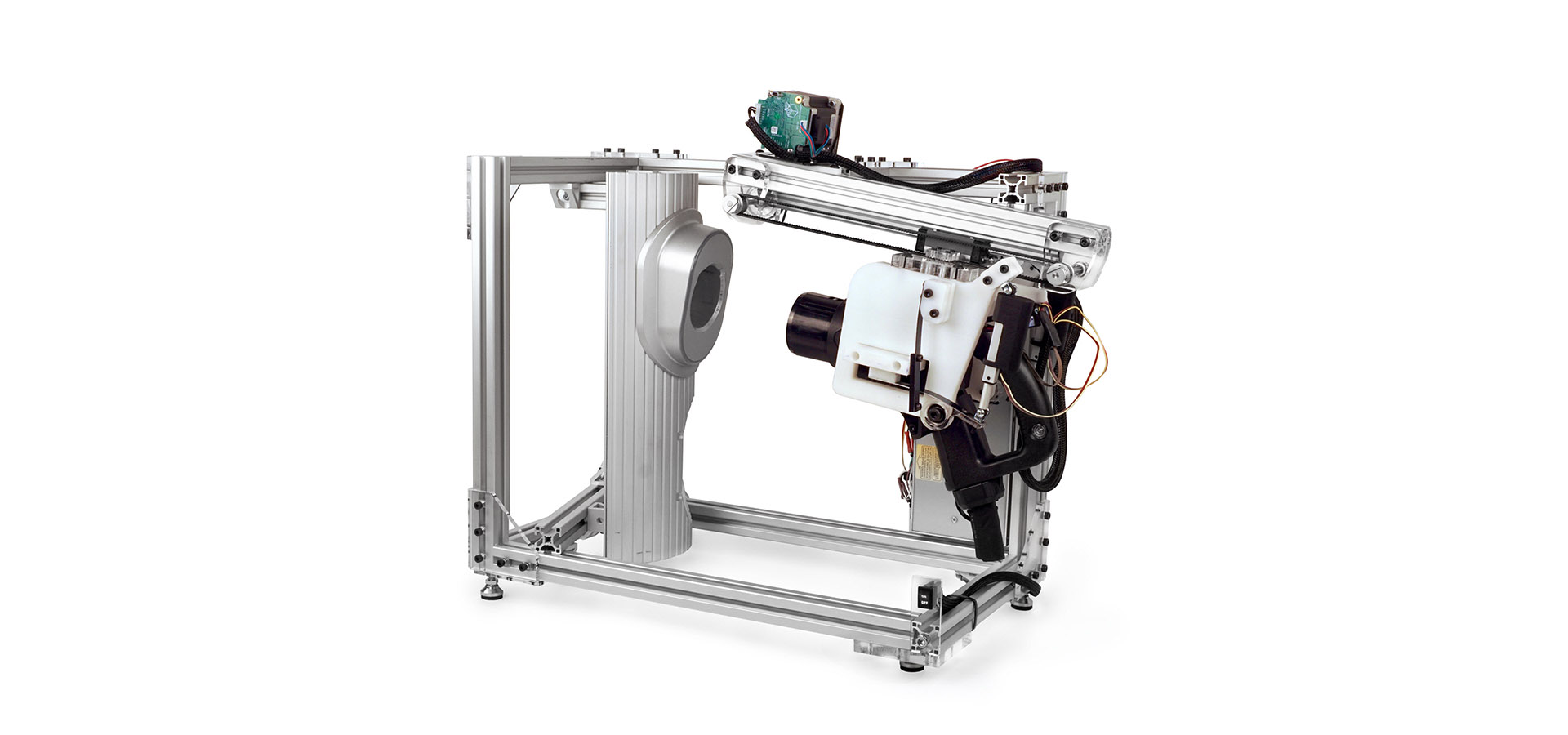

Connector Engagement Mechanism

Alloy was tasked with designing a mechanism which allowed a service technician to reliably make all connections to the power modules with one motion. The system also needed to disconnect all high voltage connections upon opening for operator safety. Each individual connection had its own X, Y, Z, and tilt tolerances in addition to the large tolerance between the module and the system. The design accounted for these tolerances with individual part float and centering mechanisms for each connection. After initial prototyping, we studied the system through detailed force-displacement testing of each connection to identify areas that required improvement. By adjusting specific tolerances, staggering the force peaks, and adjusting spring forces, Alloy was able to meet ChargePoint’s specified reliability, regulatory and usability needs.

System and Part Analysis

ChargePoint defined a set of specifications based on potential product failure modes. Alloy helped develop and run an extensive suite of analyses and validation tests to meet those specifications. Part and system design work was coupled with FEA modeling and hand calculations to ensure the subsystems met the required safety factor. Analyses included part abuse loading, high force winds, vandalism, cyclic wear on moving parts, part tolerance, and thermal expansion. To validate this work, we designed and built test fixtures and tested full prototypes of these designs. Changes based on validation testing were incorporated into the final part designs. The final proven design met an extensive set of requirements ensuring product safety and reliability.

Project Management

Alloy worked with a growing multi-disciplinary ChargePoint team to develop the Express 250. This complex product had tight release timelines and many risks requiring mitigation. We helped ChargePoint with standards and processes to enable high-quality, efficient communication and cross-functional collaboration. We also led an integrated team through multiple overlapping product builds at their onsite manufacturing facility. This work helped us build trusting relationships and enabled ChargePoint to deliver high quality products on tight timelines.