Our Services

Our Services

Our Services

Our Services

Our Services

Our Services

Our Services

Our Services

Our Services

Our Services

Our Services

Our Services

Within our core disciplines of mechanical, electrical and firmware engineering, Alloy has developed in-house services to support projects from early concept development through manufacturing ramp support. Our seasoned project managers apply disciplined process, broad experience and inclusive collaboration to weave these services together and reach our clients’ goals effectively and efficiently. We also draw on an extensive network of partners and vendors to bring in project-specific expertise as needed.

Mechanical Concept Development

Alloy specializes in developing clever, elegant, and robust mechanical concepts to solve difficult engineering problems.

• Mechanism design

• Tight component packaging

• Mechanical product architecture

• Structural design

Electrical Engineering

Our Hardware Engineering team provides Electrical Engineering expertise to develop integrated hardware designs for a wide variety of products.

• Schematic Design

• PCB Layout

• Embedded Systems

• Bluetooth, Wi-Fi

• Batteries, displays, sensors

• FPGA

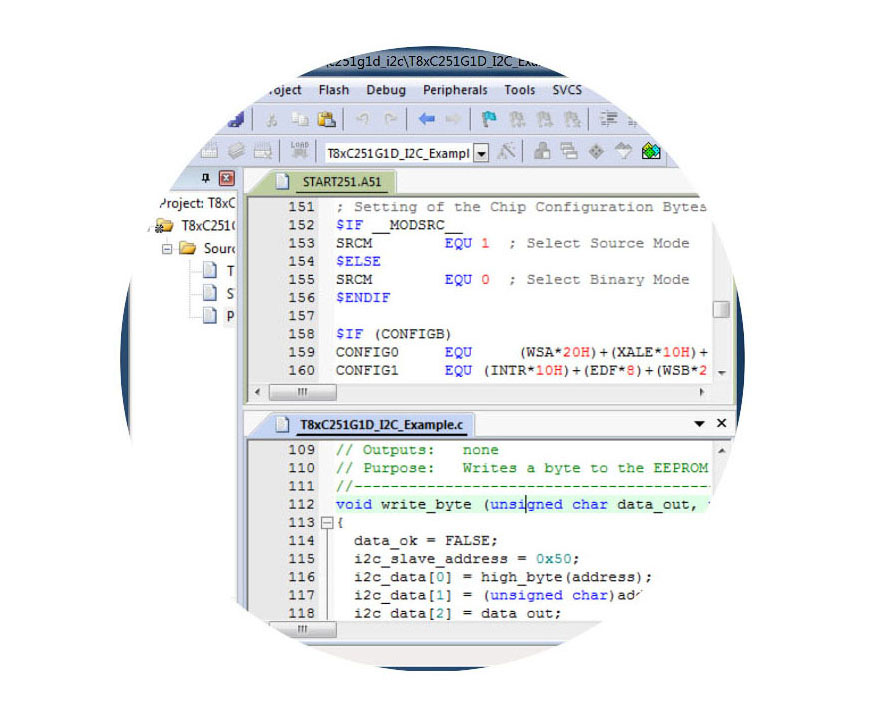

Firmware Development

Firmware breathes life into the PCBAs we develop. We design our hardware and firmware together to produce optimized solutions.

• Bare-metal

• Real-Time Operating System (RTOS)

• Embedded Linux

Detailed Design for Manufacturing

We use the latest CAD tools and deep knowledge of many manufacturing processes to develop tool-ready data for custom mechanical and electrical components. Extensive production ramp experience informs the designs.

• Top-down driven 3D CAD Data

• Schematics and layouts for PCBs

• Design for manufacturing and assembly

• Assembly fixture design

• 2D Drawings including GD&T

• BOMs and assembly instructions

Industrial Design Integration

Early collaboration with clients and designers improves the mechanical integrity and manufacturability of the industrial design. We then work diligently to maintain the ID goals throughout development and manufacturing.

• Component configuration studies

• Design feasibility review

• Ergonomics and fit prototyping

• Complex CAD surfacing, C3 continuity

• Creative assembly and finish strategies

Prototyping

We are always searching for ways to build better prototypes faster. To augment our onsite capabilities, we have a go-to list of reliable resources for fabricating just about anything.

• Onsite CNC machining

• Onsite high-resolution 3D printing

• Onsite laser cutting

• Onsite assembly and refinement

• Prototype vendor management

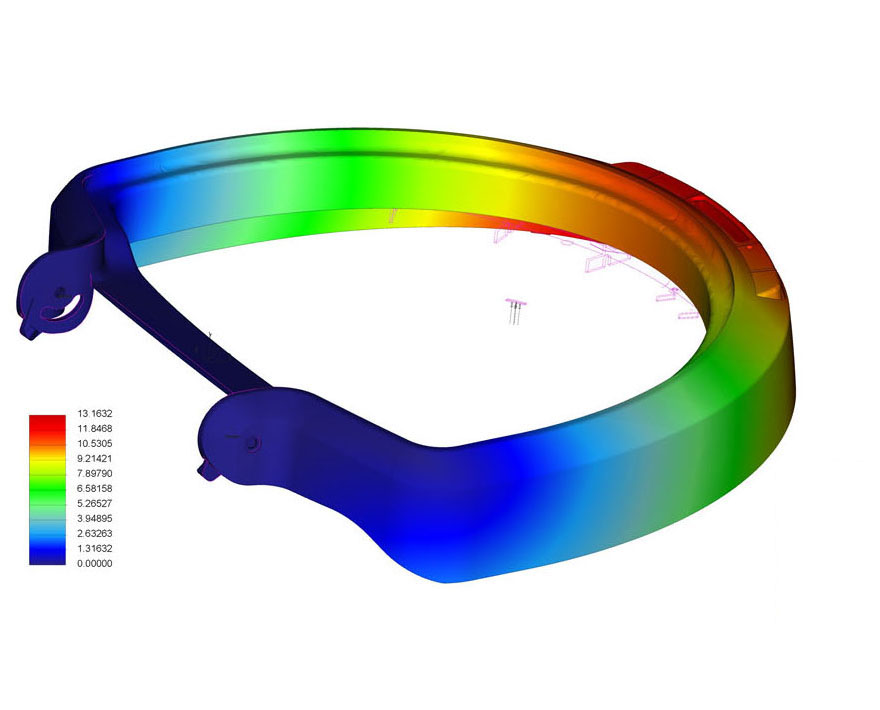

Analysis and Testing

We apply mathematical analysis and computer simulations to predict results and provide direction. Comparing analysis with real world tests builds confidence in digital iteration and leads to more effective prototyping.

• Kinematics (motion modeling)

• Force profiles (static and dynamic)

• Structural analysis

• Tolerance analysis

• FEA (dynamic, non-linear, basic thermal)

• PCBA functional testing

• Digital force profile capture

• Drop, cycle and strength testing

• Ultra-high-speed video

• Ergonomic fit and feel testing

• Noise and vibration testing

Medical

Alloy has experience with many of the special considerations for medical device development.

• Verification & Validation plans and execution

• Client QMS support

• IEC 60601-1 safety requirements

• Coordinating pre-clinical trials with IBUs

• Short-run builds for clinical trials

• ISO certified suppliers and testing labs

• Biocompatible material selection

Vendor Liason

Every vendor has a unique set of capabilities and preferences. We work closely with them to play to their strengths where possible and offer creative solutions as needed.

• Preparation of RFQ packages

• Vendor capability evaluation

• DFM/DFA negotiation

• Engineering sample reviews

• Tooling design and part sample review

• Mechanical and Electrical test oversight

• Cp/Cpk dimension review

• Onsite production ramp support